What is a Toggle Clamp?

Sandfield Engineering are one of the UK’s leading toggle clamp suppliers, so who better to answer the question – What is a toggle clamp?

A toggle clamp is a tool that you use to securely locate components or parts in position, typically, but not exclusively, as part of a production process.

The primary features of a toggle clamp are that it locks securely in place and is quick-acting. Toggle clamps can be engaged and disengaged rapidly, which is why they are commonly found on production lines where components need to be held firmly and removed quickly in repetitive manufacturing processes.

What are the different types of Toggle Clamp?

There are a series of different types of toggle clamps, which are most commonly defined by their action.

There are six main types of toggle clamps, including vertical toggle clamps, horizontal toggle clamps, plunger toggle clamps or push action toggle clamps, hook action toggle clamps, plier action toggle clamps and cam action toggle clamps.

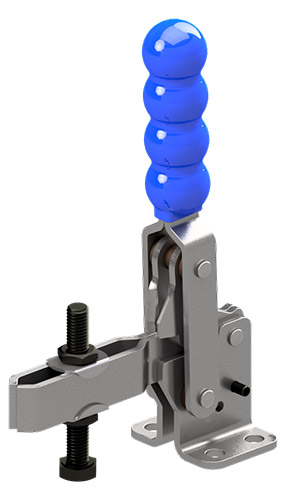

The most common toggle clamp is a vertical toggle clamp or a vertical action toggle clamp. Vertical toggle clamps are characterised by a bar that swings down and clamps vertically onto the components. The handle, in its closed position, is in a vertical or upright orientation.

The most common variation on the vertical toggle clamp is called a horizontal toggle clamp or a horizontal action toggle clamp.

Horizontal toggle clamps apply holding force in the same downward direction, but the handle is, in its closed setting, in a horizontal position. This allows for the use of a toggle clamp in instances where you need more clearance above the clamp or where you need the operator’s hand to be away from the clamp during operation. These are the applications where horizontal toggle clamps have the advantage.

The third most common toggle clamp is called a plunger action toggle clamp, push action toggle clamp or push-pull toggle clamp, which, as the names suggest, are push or pull action clamps.

These toggle clamps apply the force in a direct, straight-line direction. The clamp toggles in the forward and rear positions. This is particularly useful in situations where you may occasionally require the clamp not only to push forward and apply the force but also to pull and apply the force in reverse. This has the advantage that, when the clamp is mounted vertically with the handle in the back position, it will stop components falling forward, as the handle is behind the component in the locked position.

The fourth most common toggle clamps are called hook action toggle clamps. Hook action toggle clamps are most often used to pull components together. There are two types: U-bolt hook action toggle clamps and single-bolt hook action toggle clamps.

Hook action toggle clamps are quite often used to retain or hold lids onto items or when using injection moulding tools that hinge – these are often held together with hook action toggle clamps. Hook action toggle clamps are also used for securing doors and are ideal in any application where you need to pull two separate items or components together.

Another option is a cam action toggle clamp. One of the challenges of using toggle clamps is that they normally require the component thickness to be consistent. Toggle clamps don’t like variation. Although there are different methods to adjust for variation, the most straightforward solution is to use a cam action toggle clamp.

A cam action toggle clamp works on a cam, which allows for a component variation, depending on the model, from one to three millimetres. Cam action toggle clamps work with a handle that moves across a counter and then locks the component into position, rather than using the toggle linkage system found in other types of toggle clamps.

Perhaps the least common type of toggle clamp is the plier action toggle clamp. Plier action toggle clamps are hand tools that operate with a squeezing motion to pull components together.

They are hand-applied tools often used in fabrication processes, although they can also be found in the automotive industry. Plier action toggle clamps are reasonably flexible, with the option of making custom jaws to match your components precisely.

What materials do you use for toggle clamps and why?

Standard or light-action toggle clamps are usually made from pressed steel components with a zinc-plated finish.

Stainless steel is also an option for producing toggle clamps, depending on the environment that you are working in. In regulated industries where hygiene is important, like the food industry and pharmaceuticals, stainless steel toggle clamps are often specified.

If the toggle clamp is to be used outside, in marine applications or harsh environments, you will need a certain amount of corrosion resistance and stainless steel is often used in those applications. In particularly harsh environments, we have produced toggle clamps using 316 stainless steel, which offers even greater corrosion resistance.

Whilst most toggle clamps have zinc plating applied, there are a couple of other options for specialist applications. Toggle clamps may also be chemi-blacked for use in environments where light and reflections are a consideration. For example, if you are using laser guidance or location systems. Stainless steel plating can also be applied if a limited amount of corrosion resistance is required.

Sandfield Engineering also manufactures a range of heavy-duty toggle clamps which are made from castings. These are heavier-duty and more robust than pressed steel clamps.

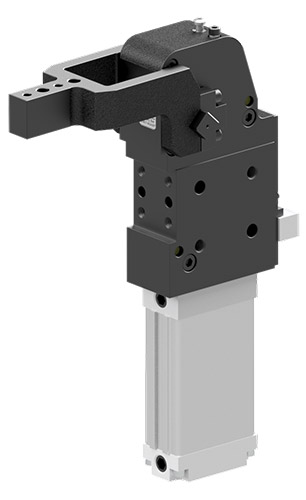

What is a heavy-duty toggle clamp and what does heavy-duty actually mean?

Heavy-duty toggle clamps differ from standard toggle clamps in that they have a more robust construction. You would normally use castings for the handles and links and they have larger diameter pins and bushes which are hardened and ground. Heavy-duty toggle clamps are more durable and tend to be used in areas where there’s higher production, potentially more weld debris or where you need a longer service life.

A heavy-duty toggle clamp should be specified if it’s going to be used in a harsh environment, with higher clamping forces, higher holding forces and greater production numbers. Heavy-duty toggle clamps were originally developed for the automotive industry, where they required high levels of production, strong clamping forces and reliability.

What kind of applications are toggle clamps used in?

Toggle clamps are used in a wide range of applications where you need to securely hold a component and apply a process to it. This could be part of a welding fixture, a glueing process or simply holding a part down to drill or ream a hole. Almost every kind of manufacturing process can benefit from using toggle clamps.

The automotive industry is one of the largest users of toggle clamps, particularly in “Body in White” areas, where panels are welded, riveted or bonded. Toggle clamps are used throughout production lines, but they are also suitable for one-off jigs or fixtures where accurate, secure holding is essential.

They can also be used on equipment such as sieve lids, in glueing or bonding operations in the woodworking industry or in any situation where quick and secure clamping and release are required.

Which type of toggle clamp should I use?

The first thing to consider is the type of action you need: vertical, horizontal, hook, plier, plunger or cam action. This depends on whether you need to simply hold a component in place, apply pulling force or work within limited space around the clamp.

Once you’ve determined the action, the next consideration is material. Do you need a stainless steel clamp for a clean or corrosive environment or is mild steel sufficient?

You’ll also need to think about the level of force required and whether a heavy-duty toggle clamp is needed. This depends entirely on the application and what you’re trying to achieve.

The size of the components, any variation between parts and the required access around the clamp (these are all important). For instance, you may need space for a welding gun or milling cutter or require extra clearance for safety.

It’s also worth considering whether the clamp needs a secondary lock. For example, if the clamp is used in a vibrating environment or to secure items in transit, secondary locking ensures the clamp remains secure throughout use.

If you still need a hand choosing the right toggle clamp, use our interactive tool to help you arrive at the right option for your application.

What is the benefit of using a toggle clamp over other types of clamp?

One of the main advantages of a toggle clamp is that it is quick-acting. Simply applying the handle immediately applies the load and secures the component in place. Compared to other clamping systems like strap clamps, toggle clamps are significantly faster and easier to use, particularly where components need to be clamped and released quickly.

Toggle clamps also generate high holding forces from a relatively small input of effort. This makes them more efficient than many alternative clamping methods.

Ultimately, the biggest benefit is increased production efficiency. If you’re currently using slower clamping methods, switching to toggle clamps can lead to cost savings by speeding up both loading and unloading times and increasing overall output.

How to maintain toggle clamps

To ensure a long service life, we engineer our toggle clamps to be as robust as possible by using hardened and ground bushes wherever we can and fitting larger pins where appropriate. Our aim is always to maximise the durability and reliability of each clamp.

When it comes to maintenance, the key is to keep components clean, especially in environments with a lot of debris and to lubricate them regularly to maintain smooth operation. In most cases, if they are used and specified correctly, toggle clamps should last a long time with minimal upkeep.

Do not hesitate to get in touch to speak to us about how we can help you find the right toggle clamp.