Vertical Toggle Clamps vs Horizontal Toggle Clamps

Wondering about the difference between vertical toggle clamps and horizontal toggle clamps, and which is best for your application? This guide explains how each toggle clamp works, where they’re used, and how to choose the right option for your setup.

Toggle clamps continue to provide an essential purpose in working environments across a variety of applications and industries by improving efficiency, safety and quality. From woodworking and metal fabrication to automation and CNC machining, they provide fast, reliable and repeatable clamping solutions.

Among the many types of toggle clamps available, vertical toggle clamps and horizontal toggle clamps are two of the most commonly used.

Understanding the difference between them will help you select the most effective clamp for your workspace, load requirements and available clearance.

The Difference Between Vertical and Horizontal Toggle Clamps

To understand the best type of toggle clamp for your needs, let’s start by looking at the difference between vertical and horizontal toggle clamps.

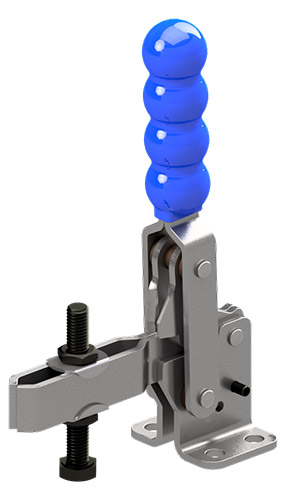

Vertical Toggle Clamps

Hence the name, vertical toggle clamps are defined by a handle that moves vertically (up and down), which applies force from above.

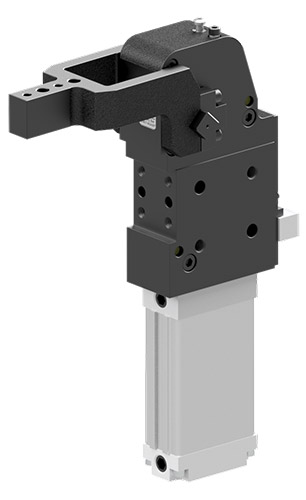

Horizontal Toggle Clamps

The handles on horizontal toggle clamps remain parallel to the work surface. This makes them ideal for securing objects against vertical surfaces or edges, or where overhead clearance is limited.

The key difference between vertical and horizontal toggle clamps is the orientation of the handle when engaged. This difference directly affects how and where each toggle clamp can be used. Vertical toggle clamps require sufficient space above the clamp to engage the handle, while horizontal toggle clamps are better suited to tighter environments.

With these core differences established, let’s explore the defining characteristics of each type in more detail.

Defining Characteristics of Vertical Toggle Clamps

Here is a simple overview of the design, performance and typical applications of vertical toggle clamps:

- Design – The vertical orientation applies a strong downward clamping force, securing the workpiece firmly in position.

- Clamping force – Vertical toggle clamps are available in a wide range of sizes and configurations, with forces ranging from around 200 to 400 Newtons up to more than 2,500 decaNewtons for heavy-duty applications.

- Typical applications – Vertical toggle clamps are commonly used in jigs, fixtures and assembly lines across woodworking, metalworking and automation environments.

You can view the full range of vertical toggle clamps available from Sandfield Engineering in our toggle clamp product selection.

Defining Characteristics of Horizontal Toggle Clamps

Below is a list of the same key features that distinguish horizontal toggle clamps:

- Design – The horizontal handle orientation applies an easier clamping force parallel to the mounting surface, allowing the clamp arm to move sideways to secure the workpiece while keeping the handle clear of the clamped area.

- Clamping force – Horizontal toggle clamps are available in a wide range of sizes and configurations, with clamping forces typically ranging from 2,000 Newtons (450 lbs) to 5,300 Newtons (1,200 lbs).

- Typical applications – Horizontal toggle clamps are ideal in situations where space is limited, but accuracy is important. For example, as fixtures for CNC machines alongside woodworking projects and metalworking.

The Benefits of Vertical Toggle Clamps

Vertical toggle clamps are widely used due to their simplicity, strength, and ease of operation. Their design makes them particularly effective in applications where downward pressure is required.

- Strong downward clamping force – The vertical handle action applies consistent pressure from above, helping to securely hold workpieces in place during machining or assembly.

- Quick and easy operation – Vertical toggle clamps allow fast engagement and release, improving workflow efficiency in repetitive tasks.

- Clear access to the workpiece – When disengaged, the handle moves out of the way, providing unobstructed access for loading and unloading parts.

- Versatile across industries – Commonly used in jigs, fixtures, and assembly lines across woodworking, metalworking, and automation.

Reliable and repeatable clamping – Ideal for applications that require consistent positioning and repeat accuracy.

The Benefits of Horizontal Toggle Clamps

Horizontal toggle clamps offer a compact and space-efficient solution, making them ideal for environments where clearance is limited but precision is essential.

- Space-saving design – The horizontal handle orientation requires minimal overhead clearance, making these clamps suitable for tight or confined work areas.

- Improved accessibility – Keeps the handle clear of the clamping area, allowing easier access to tools and workpieces.

- Precise and controlled clamping – Well-suited for applications where accuracy and repeatability are critical, such as CNC machining and fabrication.

- Side clamping capability – Ideal for securing workpieces against vertical surfaces or edges.

- Adaptable to multiple applications – Commonly used in CNC fixtures, welding setups, woodworking, and metalworking environments.

Final Verdict: Vertical Toggle Clamps vs Horizontal Toggle Clamps

Both vertical and horizontal toggle clamps provide reliable and efficient clamping solutions, but the right choice depends on your working environment and application requirements.

Vertical toggle clamps are best suited to applications requiring a strong downward force and clear access from above. They perform particularly well in jigs, fixtures and assembly lines where overhead space is available.

Horizontal toggle clamps are better suited to tighter spaces where overhead clearance is limited. Their side clamping action makes them ideal for CNC fixtures, vertical surfaces and applications where space efficiency and precision are critical.

Ultimately, neither option is better in every situation. By considering factors such as available space, required clamping force and workpiece orientation, you can select the toggle clamp that best supports efficiency, safety and precision in your workflow.

Need Help Choosing the Right Toggle Clamp?

Sandfield Engineering supplies a wide range of toggle clamps, including both vertical and horizontal options, designed for industrial use and long-term reliability.

You can explore our full toggle clamp range, browse individual toggle clamp products, or learn more about what a toggle clamp is and how it works to help inform your decision.

If you need advice on selecting the right clamp for your application, our experienced team is always happy to help. Get in touch today.