At Sandfield Engineering we enjoy a challenge, it keeps us on our toes which keeps our customers happy and coming back for more.

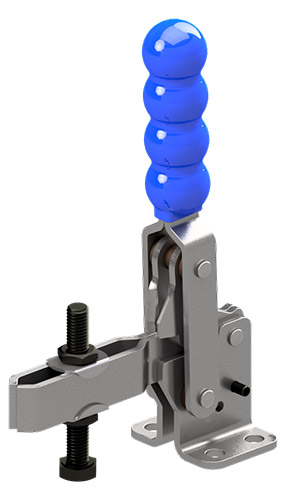

We have been supplying Comau with Toggle Clamps and Pneumatic Clamps for decades so it made absolute sense that when they were designing a new production line for a new model for Volvo requiring a custom-designed Pin Clamp they came to Sandfield Engineering to support them in the development.

The pin they required was only 16mm to suit the design of the new car body, something other suppliers had been unable to provide.

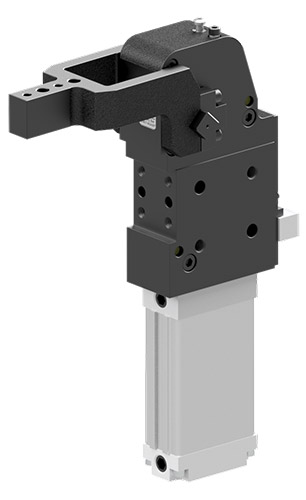

The Pin Clamp solution that they needed had four particular requirements.

Firstly, the Pin Clamp would have to conform to the shape of, and fit inside, the underbody panel of the vehicle.

Secondly, they wanted some kind of manual release.

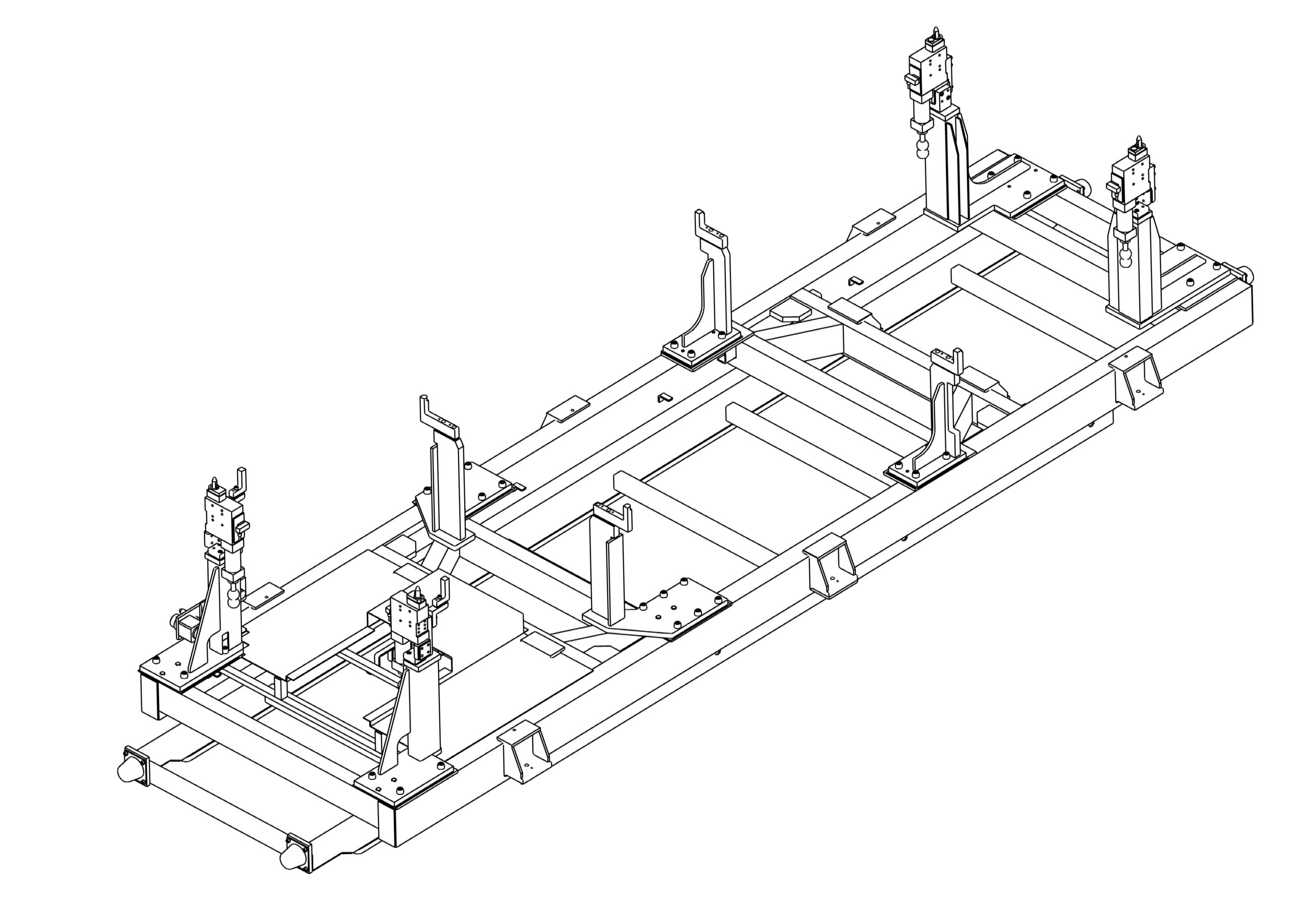

Thirdly, the pallet that they were clamping the body component to required six-pin clamps with a combination of three pin sizes, plus a variation where some of the units had a location pad for the panel to sit on, and others didn’t.

The last, and the most challenging requirement was the 16mm Pin.

If you have experience working with Pin Clamps you will know that a 16mm pin is tiny, you will also know that the pin size is dictated by the thickness of the panel. If the panel requires a 16mm pin there is no alternative other than to use a 16mm pin, even though at that time we weren’t aware of anybody successfully implementing a Pin Clamp with such a small pin.

Challenges and Objectives

The first requirement, adjusting the shape and size of the Pin Clamp so that it would conform to the shape and fit inside the body panel wasn’t particularly challenging. Sandfield provides a range of Underbody Clamps to a host of automotive manufactures and this is always a requirement. We have developed our whole range of Pin Clamps so that the size and shape are adaptable for precisely this reason.

Secondly, providing a manual release also didn’t pose much of a challenge. One of the challenges of using Pin Clamps is that, because they have moving parts – the pin and hook mechanism, they tend to be prone to contamination from weld splatter or glue. This can cause the clamp to stop activating or get stuck in the on position. If a pneumatic clamp sticks in the activated position it is very difficult to remove the component from the clamp. This often requires the panel to be cut off which can be costly if you consider that the panel is most likely no longer usable and it is an obvious disruption to the affected production line for a period of time. We have posted more about effectively using Pin Clamps and the innovations we have come up with to address this particular issue, including manual releases, here.

The third issue, the six-pin clamps with different pin sizes with a variation for location pads for clamping the pallet also didn’t represent an issue. This was simply a matter of specifying these Pin Clamps and adapting them from our existing products. The only innovation we provided here was to colour code the clamps to make it easier for operators to identify which clamp was performing each function.

It was the fourth requirement, the 16mm pin that was going to be difficult.

If you know about Pin Clamps or Underbody Clamps you will know that they are essentially locating and clamping units used primarily in automotive manufacturing processes to securely hold vehicle panels to fixtures during assembly.

The active components of a Pin Clamp are the hook and the pin. The pin locates the components and the hook is the clamping mechanism that pulls and holds the panel onto the fixture. Whilst the pin is locating the component the hook is housed within the pin, when the Pin Clamp is activated the hook emerges to hold the panel in place, when the clamp is deactivated the hook retracts into the pin and the cycle starts again.

If you are following this, you will appreciate that the pin has to house the hook, and a tiny pin necessitates a tiny hook. The challenge is that this hook has to generate the required clamping force to securely hold the component whilst the assembly is undertaken. The smaller the hook, the less material you are able to use and the weaker the hook will be. So, the crux of this challenge is how to produce a hook that is strong enough to sustain the required pressure whilst being small enough to be contained in a 16mm pin.

How Sandfield Engineering went about solving this tiny pin challenge

The strength issue meant that we weren’t going to resolve this tiny pin conundrum by simply downsizing the pins that we offered on other Pin Clamps that we supply.

The only two real opportunities for overcoming this challenge were to review both the design of the pin and the materials that we use.

To ensure the strength of the new clamp despite the small pin, we worked on the design of the hook and the pin to optimise their strength. Working with our metal suppliers we researched and tested a range of different metals before settling on specialised steel that we put through a hardening process to increase its strength.

The outcome of this 16mm Pin Clamp challenge

Within a week of Volvo’s initial enquiry we confirmed to them that we believed we could do the job, we provided them with prototypes within three weeks of them approving the concept.

We started producing production parts six weeks after creating the prototypes, supplied the components for the complete production line, and subsequently carried out two or three different deliveries and programs of the same units.

The clamps completed over 1.8 million cycles over a ten year period and the feedback from the client is that our Pin Clamps were outlasting comparable products from our competitors by three or four times.

Consistent with automation production schedules when the next model went into production Volvo came back to us for more Pin Clamps and we provided them with a variant customised to the new production line.