Worcestershire, UK

Sandy Lane, Stourport, DY13 9QB

Send us a message

We reply within 1 day

+44(0)1299 823158

Available 9am - 5pm, Mon-Fri

Sandy Lane, Stourport, DY13 9QB

We reply within 1 day

Available 9am - 5pm, Mon-Fri

Shop hundreds of Toggle Clamp options from Sandfield Engineering – the clamp experts since 1965.

Sandfield Pneumatic Clamps are ideal for automated or repetitive holding applications.

The toggle clamp is a really flexible tool for repetitively holding down work pieces.

The range of clamps available is eye-watering with different sizes, different actions and different ways of mounting them to suit just about every application.

To help explain the many features of the clamps we have prepared this document to explain the many different mounting options.

Base Mounted • Template Mounted • Front Mounted • Nose Mounted

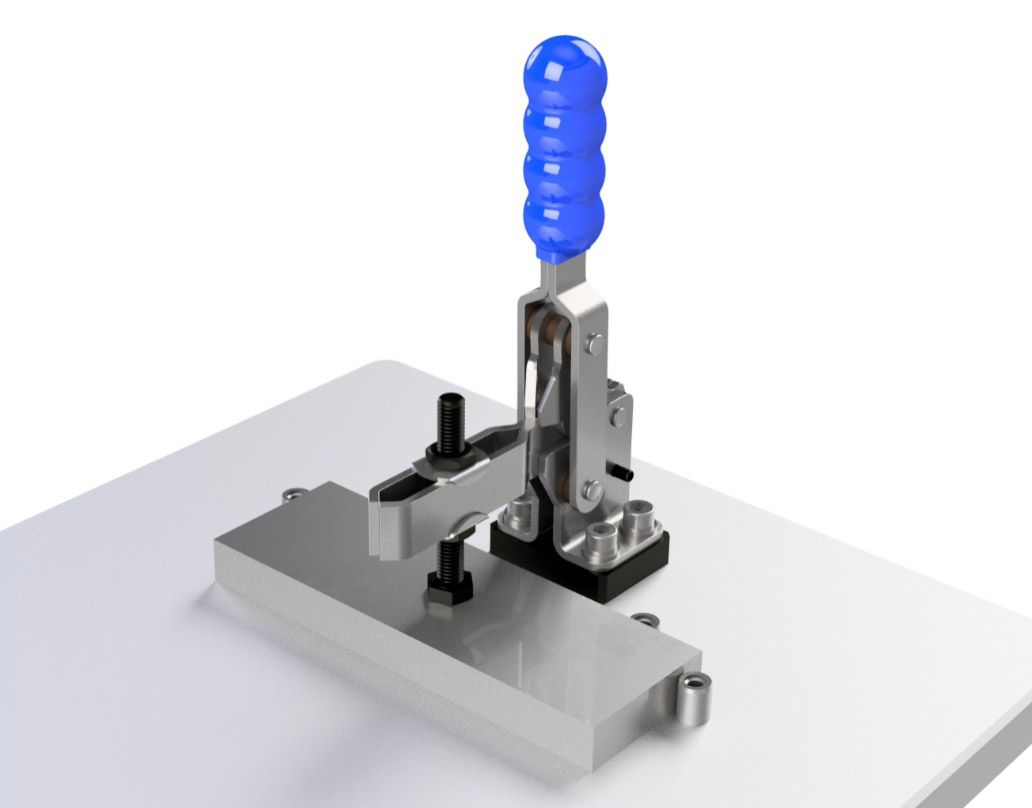

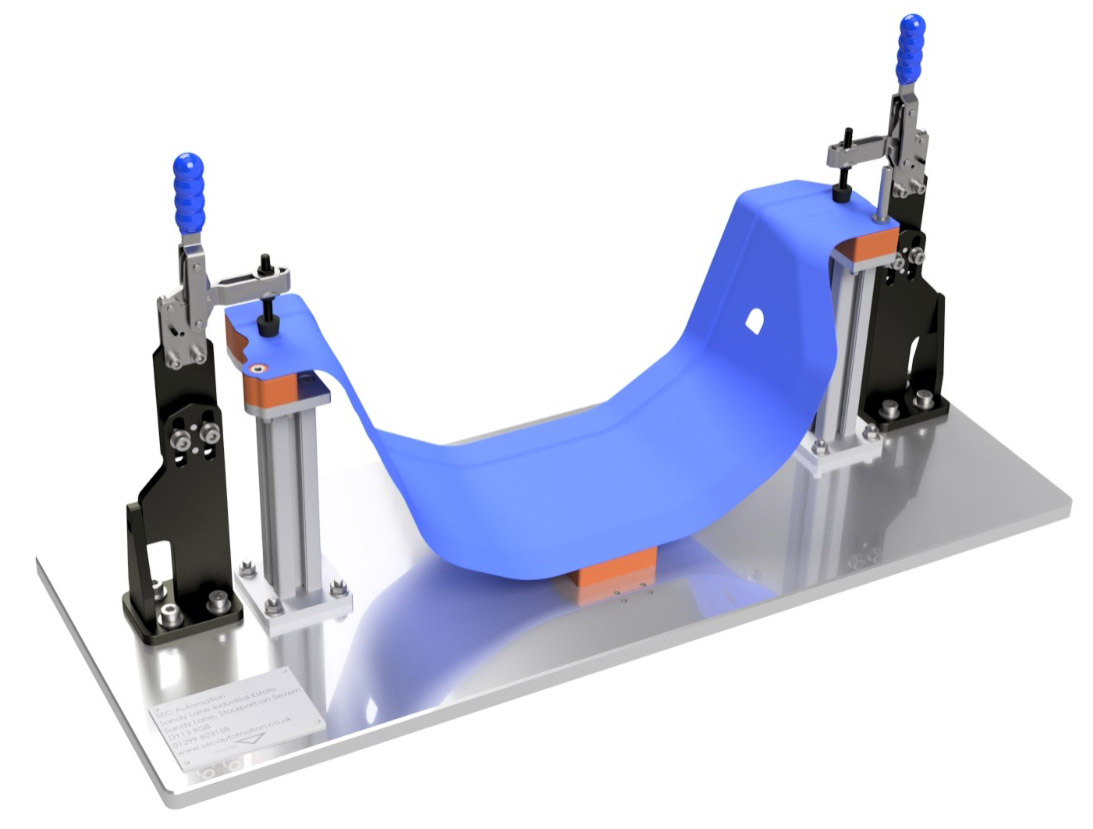

Base mounting is where the clamps are fixed to a flat surface at their base. This is by far the most common option for a toggle clamp and more than 80 percent of the clamps we sell are base mounted. Some examples include:

If there is insufficient height between the underside of the bar and the mounting surface the clamp can be raised up on a blocker or packing piece.

Very similar to previously described, the clamps are fixed to a flat surface or table. These clamps may also be mounted vertically or at different orientations to suit the direction of the force you need to apply. The clamps are supplied in a range of heights and strokes to suit many different applications.

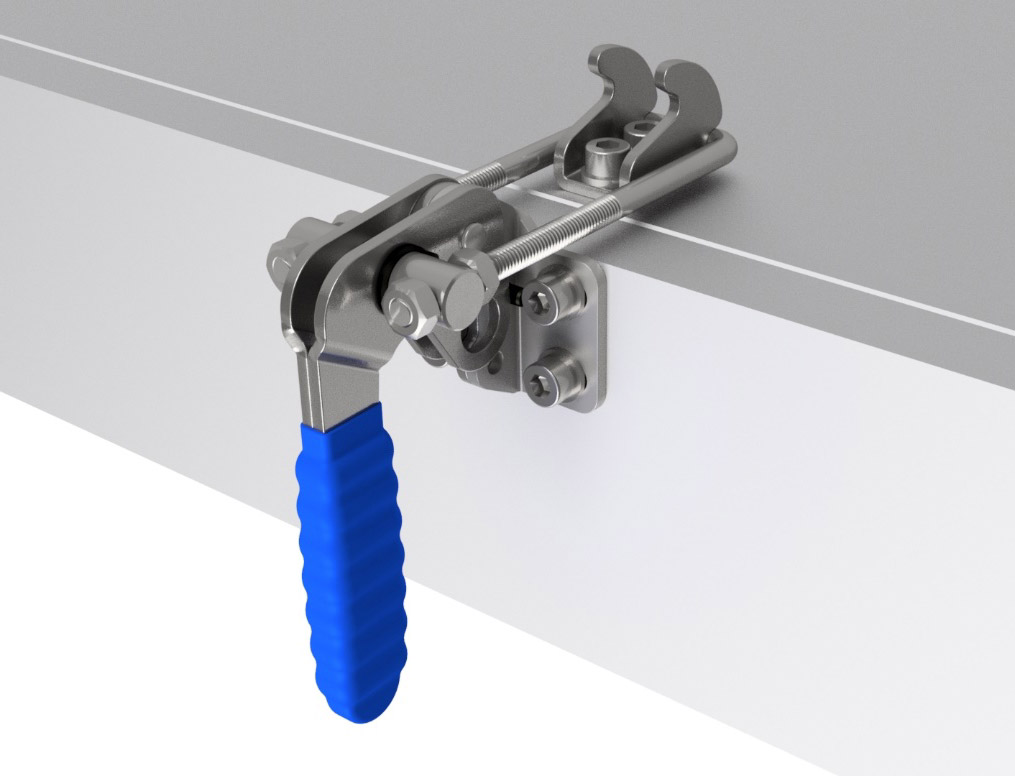

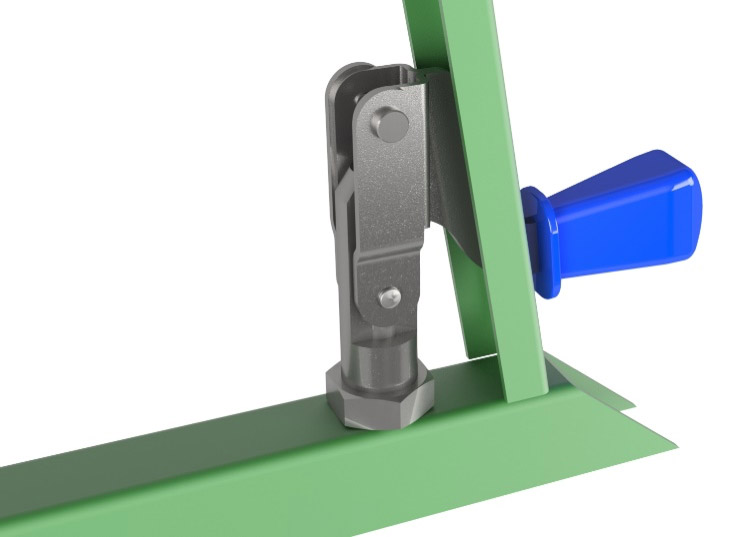

The latch or hook clamps are a base mounted clamp, the clamp can be mounted on a flat surface either horizontally or vertically.

There are 2 different styles of latch/hook clamps, the horizontal variant where the U-bolt or hook is in the same plane as latch plate or the vertical variant where the latch plate is perpendicular to the clamp.

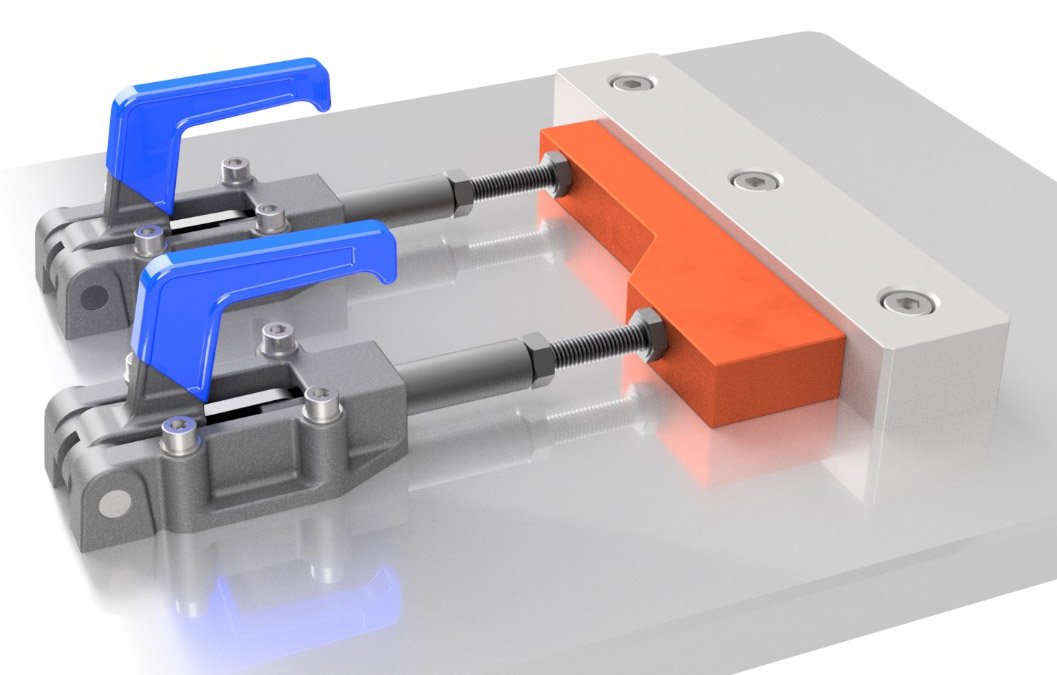

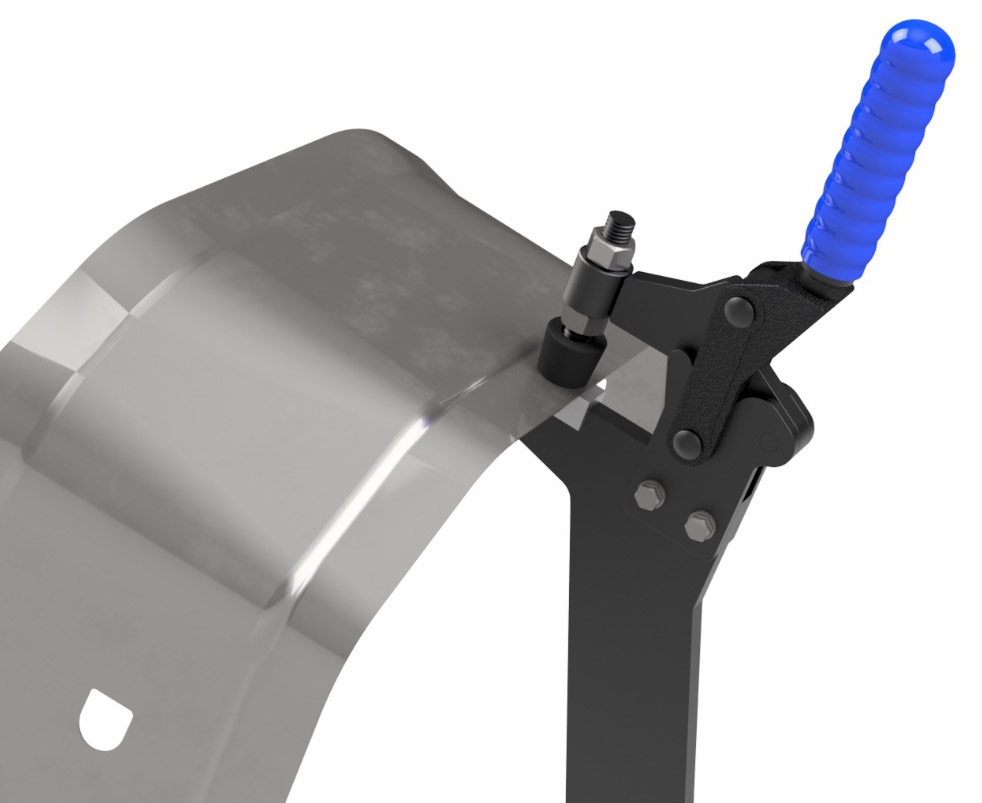

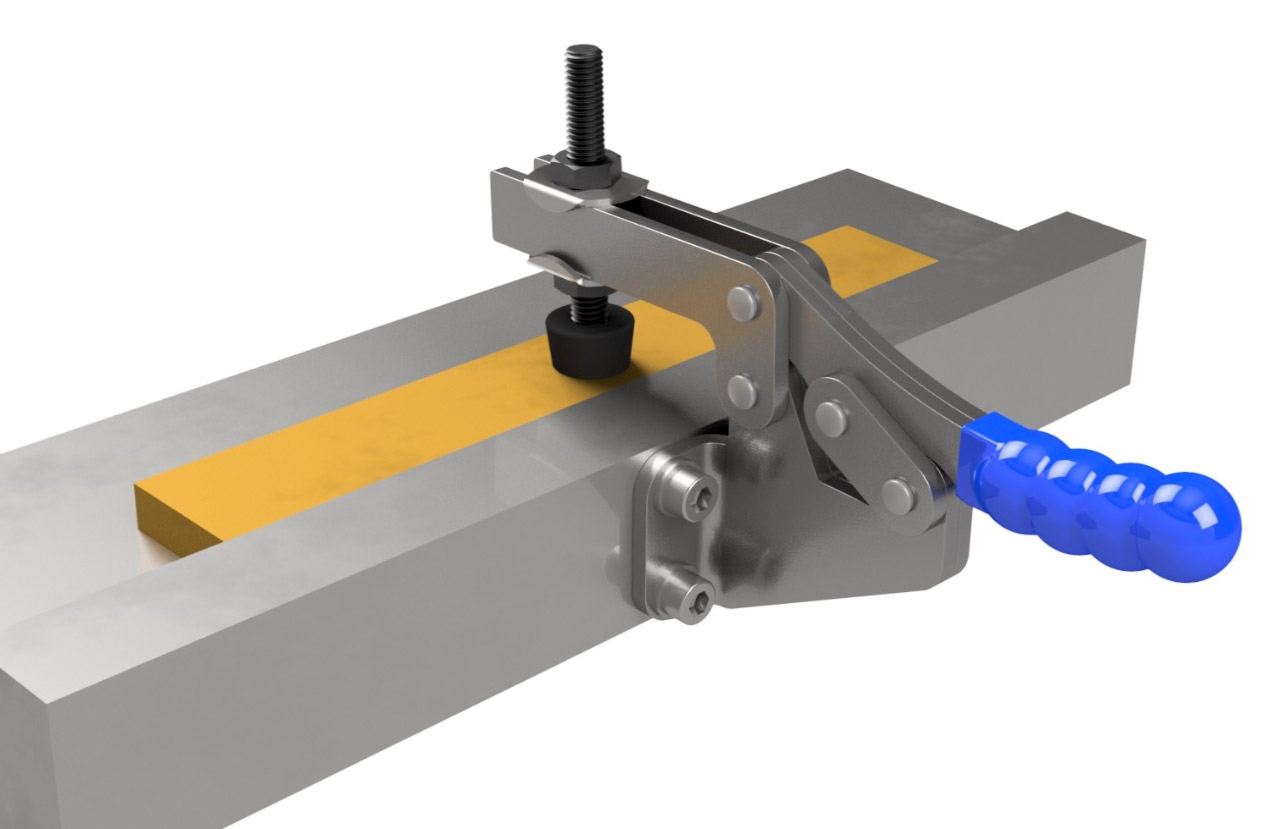

Another common mounting method is template or blade mounting. The clamp is mounted over a tenon or blade which fits between the clamp side plates. Front mounting clamps maybe a cost-effective way of mounting particularly it the clamp needs to be raised up or at complex angle. In these instances, the mounting blade for the clamp can be simply laser or profile cut and can reduce or eliminate costly machining

In addition to the clamps Sandfield also provide a range of clamp mounting towers, these are an extremely flexible cost-effective way of mounting the clamps. They are available in 3 different sizes and 3 different heights.

Some models can be front mounted, i.e., to the front of the workbench. This option is ideal where access around the work piece is limited, with a range of both horizontal and vertical clamps that may provide a perfect solution.

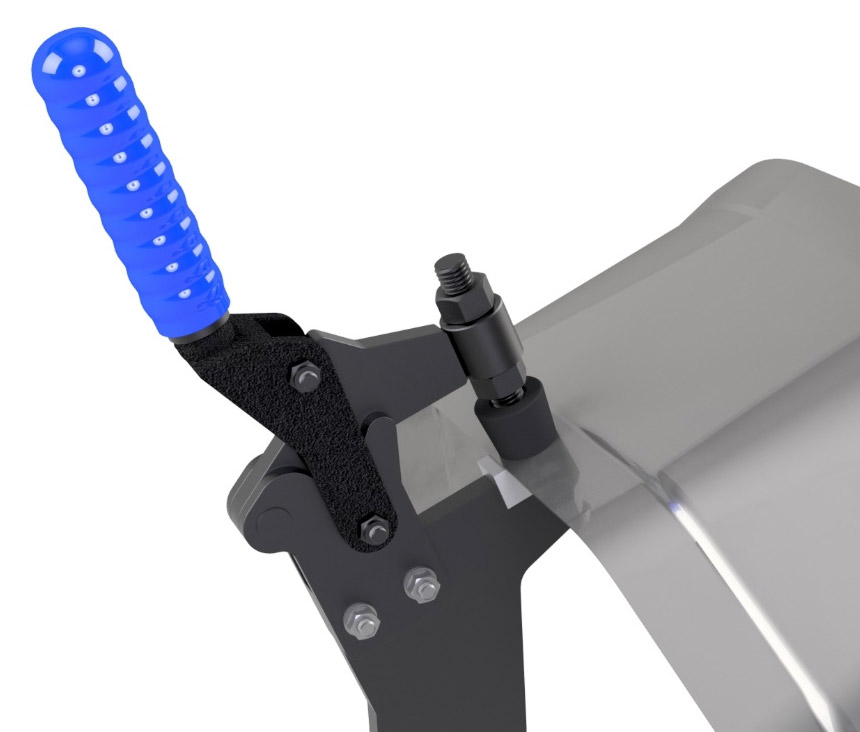

Nose mounted push pull clamps are designed with a threaded nose piece so the clamp can be mounted directly into the fixture. This is a really useful style of mounting where space is limited.

Alternatively, the clamps maybe mounted using a mounting bracket, this essentially turns the nose mounted clamps into a base mounted clamp.

Our friendly team has more than sixty years of experience and are happy to help you, no matter how impossible or unique your current manufacturing challenge might appear. Get in touch today so we can point you in the right direction.

Sandfield Engineering Company are the toggle, power and bespoke clamp experts. We design and manufacture engineering solutions that keep production lines running smoothly. We provide custom engineered solutions, prevent water pollution and drive increased efficiency through automation.

Protected by SSL Encryption

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |