At long last Japanese toilet tech makes an impact in the UK

According to The Engineer, one of the biggest cultural gaps between Britain and Japan – the technologies we apply to our toilets – is about to start closing as Japanese innovations finally start to arrive on our shores.

Japan’s electronic toilets are quite extraordinarily sophisticated and innovative. No other culture has applied such dedication and creativity to the area. They’re futuristic, they’re forward-thinking, and they reveal the country’s deep respect for ritual ablution.

The history of these marvels of engineering doesn’t originate in Japan, mind you. The first loos with integral bidets turned up in America during the ’60s, mostly in hospitals. But when Toto, the Japanese manufacturer, launched its first bidet-inspired ‘washlet’ in 1980, a separate electronic loo seat with integrated rear washing, drying and heating, Japan fell in love. And the love affair is still going strong.

These days around 80% of Japanese households have a washlet. This high level of adoption is inspiring and Toto is pulling out the stops to spread the word, as revealed by its beautiful, stylish London showroom.

Toto toilets come with all manner of tech-rich and design-led bells and whistles, including rimless design, hydrophilic zirconium glaze, unique ways of flushing that use complex CFD analysis to remove waste better and clean the bowl to shining perfection from ‘multiple entry points’, and clever twin-axis flushing systems where the water rotates both vertically and horizontally.

Right now Toto is busy making improvements to their already impressive flushing mechanism, using extremely powerful supercomputers to optimise the modelling of the ceramics. And that makes the flush even quieter, too. It also saves water, reduces maintenance, and results in fewer blockages.

The ceramic itself is also different. They’ve embedded titanium dioxide, zirconium and other minerals and elements into it to create a photocatalytic reaction that helps eliminate bacteria. The washlet even sprays a pre-mist to stop waste sticking to the bowl. When you shut the seat a UV light in the lid reacts with oxygen in the electrolysed water and the ceramic coating to break down dirt.

The list of innovations goes on… and on. Auto-close seats, heated seats, built-in deodoriser systems… and while a loo like this isn’t simple to retro-fit, Toto loos are turning up all over the place, particularly in smart UK hotels and restaurants. Now all Toto needs to do is convince the great British public that their loo can be a lot more than a mere ceramic bowl…

A gaping engineering and Manufacturing skills gap looms

WR Engineering is one of the nation’s best-respected engineering & manufacturing recruiters. They’ve recently announced a looming skills gap in our sector that’s arising fast as ‘record numbers of engineers’ retire.

A recent engineering labour market study by the ECITB showed how a worrying 91,000 engineers and 29,000 engineering technicians will have retired by 2026. Add the news that 1.8m new engineers and technically qualified people are needed to bridge various key skills gaps by 2025 and it looks like there’s a crisis brewing. If we don’t act now it could mean the British E&M sector will suffer lasting damage.

All this means engineering and manufacturing companies need to work harder than ever to encourage young people to become engineers and technicians. Whether it’s carrying out early outreach in schools and colleges, developing a powerful EVP, or bringing in flexible working hours, we need to start right now.

National Manufacturing Institute Scotland plans lodged

A report from Scottish Construction Now https://www.scottishconstructionnow.com/article/new-national-manufacturing-institute-scotland-lodged-for-planning reveals there’s a planning application in the pipeline for a National Manufacturing Institute Scotland (NMIS) centre, located in the Advanced Manufacturing Innovation District Scotland in Renfrewshire.

NMIS is a £65 million, industry-led international centre of manufacturing expertise on which the Scottish government is working in partnership with enterprise and skills agencies, the University of Strathclyde, and Renfrewshire Council. The new facility will be CO2 neutral and will be built next to Glasgow Airport. They’re planning a skills academy, a digital factory of the future, plus a collaboration hub for manufacturers, research partners, and the public sector.

Right now the application is being considered by Renfrewshire Council. Because manufacturing is crucial to the Scottish economy it’s a sector that the country wants to boost, and this marks a vital milestone along the way.

Talk to us …

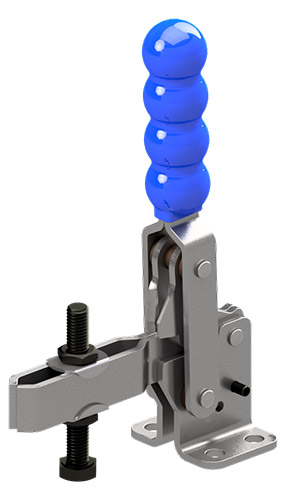

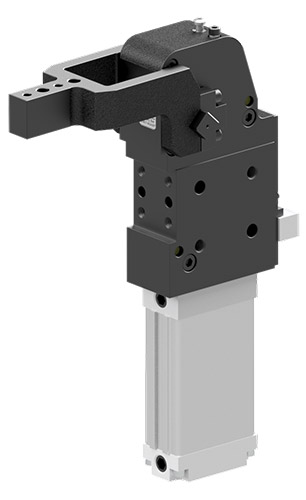

If you are looking for support with your clamps, holding challenges, industrial automation products, custom engineered solutions or your water pollution containment be sure to speak to us. Our friendly and professional team are available to offer immediate advice on all of these issues, during UK working hours, on sales@sandfieldengineering.com or +44 (0)330 223 5344.