Selective laser melting magic from Siemens

As reported by The Telegraph, the UK-based manufacturing firm Materials Solutions, bought some time ago by the German giant Siemens, is about to roll out a ‘game-changing’ metal additive manufacturing tech so innovative it’s tipped to resolve even the most complex global engineering challenges.

Siemens bought Materials Solutions in 2016, keen to tap into the company’s legendary expertise in the Selective Laser Melting technology used to craft high performance metal parts for planes, cars and power plants.

Metal additive manufacturing technology has come along in leaps and bounds recently, and now the company is ready to take their new tech to mass production. It works by allowing components to be built layer by layer, adding features as you go. This game-changing technology can produce parts designed for super-harsh environments like aviation, gas turbines, and space rockets.

All this means Original Equipment Manufacturers should be able to create components they could never have made before. Stuff like nickel-based superalloy performance parts for aerospace and lightweight parts for motor sports crafted using titanium and aluminium. In fact the technology is so revolutionary that big claims are being made. The tech is being tipped as ‘one of the essential elements of the fourth industrial revolution’, and should also drive down costs and reduce lead times.

Siemens are planning to increase the use of the technology within their own business too, with potential reduced lead times and – importantly – an opportunity to reduce emissions. The company is aiming to become wholly carbon neutral by 2030.

Job losses hit the UK’s manufacturing sector

It looks like seven is a very unlucky number right now. According to The Independent, more people lost their jobs in the UK’s manufacturing sector in November 2019 than during any other month for the past seven years. In fact job losses in the industry have hit their highest level since September 2012, as revealed by the IHS Markit/CIPS Purchasing Managers’ Index Survey.

The results showed how ‘uncertainty around Brexit’ plus redundancies and attempts to reduce costs all had an impact. It also looks like the speed of job losses hit a seven year high as businesses attempted to cut their overheads in the face of a sales crisis. Times are also proving difficult for firms because they’re still eating into the stockpiles they’d created to protect against a no-deal Brexit, rather than buying new materials and products.

As a result of this perfect storm, new orders fell for the seventh month and the fall in new orders for export is one of the worst we’ve seen for at least seven years.

Jacobs promises 2400 new UK engineering jobs

In more positive new Sharecast are reporting that the American engineering solutions company Jacobs claim they will be creating as many as to 2,400 jobs in the UK soon, when it opens its first European HQ in the capital. They already employ more than nine thousand Brits in this country and say the move proves their ongoing confidence in our economy. The jobs will, apparently, be spread over 30 existing offices and incorporate a wide range of highly-skilled professional and technical roles.

Astronaut Tim Peake calls for more investment in science

It’s been confirmed – our very own astronaut Tim Peake will be returning to the International Space Station some time before 2024.

As he points out, investing in science helps countries ‘reap future technology rewards’. So it’s good to see Britain dedicating £374million per year to the European Space Agency over the next five years, to add to the £12.3 billion already given by EU member states to fund a range of new space-led science and engineering projects.

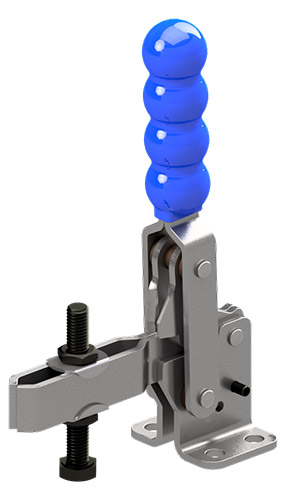

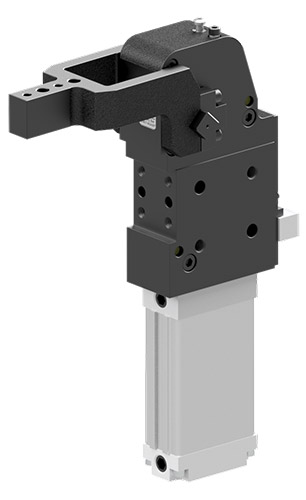

Speak to Sandfield Engineering

If you are looking to overcome your clamping and holding challenges, drive forward with your industrial automation or you need help with a specially engineered solution speak to Sandfield Engineering on +44 (0)330 223 5344 or email sales@sandfieldengineering.com for immediate, no nonsense advice.