Our current stance on the Coronavirus Situation

Just a week ago our world looked very different. This week we’re in the midst of one of the biggest health crises the world has ever seen.

We have been thinking long and hard about how we respond to this awful situation.

One of the serious concerns right now is our lack of preparedness for this pandemic.

At Sandfield Engineering we are preparing for what comes next.

At some point in this catastrophe industry will be called on to provide the things that we all need, we are already aware that there is a desperate shortage of ventilators.

We don’t make ventilators or other medical equipment and it isn’t likely that we could adapt quickly enough to start doing that, but we can support those that do.

Our business has always been about increasing the efficiency and reducing the costs for manufacturers and our commitment now is to do even better at that.

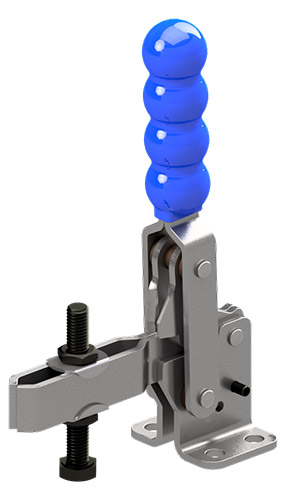

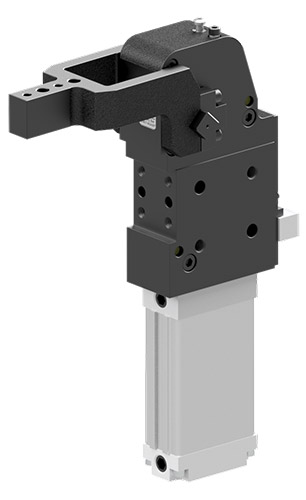

Pharmaceutical, Medical Equipment and Food manufacturers are likely to be under a great deal of pressure in the very near future. If you are tasked with increasing your production quickly we have Linear Rails, Toggle Clamps, Power Clamps, Robot Grippers and Bowl Feeders available on short lead times.

If there is anything that we could be doing to support you in your business we would be honoured to receive your call, please do not hesitate to let us know – +44 (0)330 223 5344

Engineers cautious about government’s ventilator plans

HSJ reports on the Institution of Mechanical Engineers, which represents clinical engineers, and their views on ventilator manufacture. They say it’ll be ‘several weeks, if not months’ before new ventilators will start coming off UK production lines.

Health Minister Matt Hancock says the government is already in discussion with ‘all kinds of companies’, but the most suitable is probably the motor sport sector, along with car manufacturers and military engineers. Motorsports manufacturers are already set up to make high-quality engineered products comparatively fast, to timescales other sectors would struggle with. Plus, some Formula 1 teams already have vital experience in the medical sector.

There are a few important constraints around using non-medical firms to make ventilators. They are highly sensitive medical devices, so are very strictly regulated for patient safety. While many engineering firms support the government’s plans, the right processes have to be in place before the nation can increase production.

There’s more. The IME believes companies would want compensation for sharing vital specifications and expertise with ‘non-medical manufacturers’. And of course we’ll also need more qualified Clinical Engineers to install the new ventilators safely. It looks like we have around 3000 clinical engineers in the NHS right now, working under many different job titles. Will it be enough?

Italian luxury manufacturers’ supply chain challenges

Vogue Business delves deep into China’s dramatic drop in the consumption of luxury goods. Apparently supply chains are in tatters as the Covid-19 virus continues to spread. Some Italian luxury brands are already operating at reduced capacity or have temporarily stopped manufacturing., and everybody who was asked fully expects the impact on the sector to last until mid-2021.

In the meantime the Italian government is handing down a €25 billion economic package, but that’s just the start. It’s highly likely luxury brands will also need help with financing and strategic planning for some time to come, and could also require extra support after the all-clear has been given.

Italy entered lockdown on 9th March, closing schools, banning non-essential travel and halting all commercial activities except those involved in food and medicine. So far the production and manufacturing sectors remain outside the ban, but new safety and home-working guidelines are making life tricky. In the words of Stefano Casadei, the Creative Director of the luxury shoe brand Casadei, “We had to change strategy in relation to how we communicate, how we sell, and how we operate.”

In addition to the big brands we all know, Italy is also home to 55,491 ‘micro and small enterprises’ in the textile, clothing and leather sectors, totalling 311,697 employees. In response to the crisis, manufacturers are getting creative. Alternate production cycles are being brought into play, for example, to keep the recommended distance between employees and limit the spread of the disease.

The future?

The future, of course, is impossible to predict. But perhaps, once we get used to working in these new ways, things will bed in and calm back down a little. Let’s hope so. In the meantime if you need power clamps, toggle clamps, linear rails, or anything else in the way of holding and automation kit, we’ll be pleased to help. As our clients will tell you, we’re responsive. We innovate with confidence and we deliver fast.