A Power Clamp is a heavy-duty, pneumatic, locking clamp originally designed for the automotive industry when they moved from Manual Clamping to Pneumatic Clamping to increase production outputs through automation. Power Clamps started to replace Manual Clamps and have developed from the mid 1980’s to the point where Power Clamps are now very robust, heavy-duty, and very reliable. A lot of the Power Clamp development has happened to meet the requirements of the automotive industry.

Are there applications for Power Clamps in industries other than automotive?

Although Power Clamps were originally developed for the automotive industry, and they remain the primary user, they can be used in all manner of different applications; anywhere where you need a robust clamp in an automated environment, whether that be Aerospace or any kind of metal fabrication for welding. Sandfield have supplied Power Clamps for use with incinerators, to hold oven doors closed, and occasionally in remote locations like deserts for example.

Power Clamps are used anywhere automation and clamping is involved, although not the original use Power Clamps have applications in all manner of industries.

Are there different types of Power Clamp?

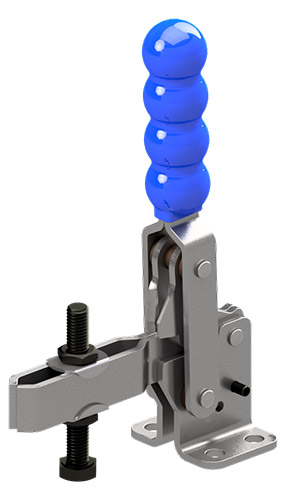

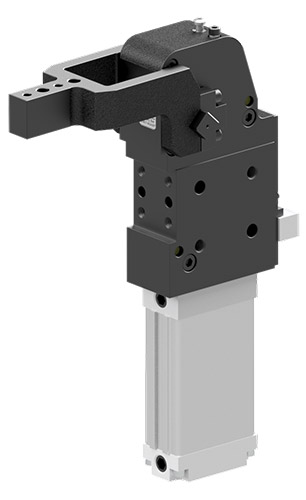

The term Power Clamp generally refers to an operation where you have an over centre clamp with an arm that pivots and rotates into the clamped, closed position. All of the clamps within the Power Clamp family perform that same function.

Power Clamps range in size from 25 bore to 80 bore. Smaller Power Clamps, from 25 to 40 bore, are typically manufactured from Aluminium which gives them reduced weight and are hard anodised for increased strength. The 50, 63 and 80 bore Power Clamps typically have Steel bodies, which gives them extra strength, makes them more robust, more resistant to damage and allows for an increased thread strength.

40 Bore Power Clamps are sometimes referred to as Gripper Clamps, especially when they are mounted on Robot Arms.

Essentially the Power Clamp itself, the function and form of it, is very similar with the only difference being the size, ranging from 25 bore up to 80 bore.

Why would you need a Power Clamp?

Power Clamps are usually used in automated manufacturing processes where the requirement is to accurately clamp components repeatedly, quickly and accurately.

Power Clamps are also useful where there is limited or no access to manually activate the clamp either because of a space limitation, manual access isn’t possible or because the clamp is located remotely. Sandfield have supplied Power Clamps for use in incinerators for example and locations as remote as deserts.

What kind of efficiency can be achieved through the application of Power Clamps when compared with manual clamps?

The efficiency comes down to a combination of speed, accuracy and reliability which is also dependant on the design of the fixture.

If you are clamping manually and you have 12 clamps, with an operator who applies each of those clamps it is going to be much quicker if you have 12 Power Clamps which are all applied instantly, automatically and simultaneously. You will achieve the same efficiency when it comes to unloading the components with all 12 clamps disengaged automatically and simultaneously. In this instance you could argue that Power Clamps are 24 times quicker, except of course, a Power Clamp is applied much more quickly than a manual clamp, so it is more accurate to say theat Power Clamps are at least 24 times faster.

Power Clamps also provide for a more accurate and repeatable process It also saves time and money by reducing the number of errors in production, which, if unchecked, could lead to a faulty end product.

The efficiency that is achieved will depend entirely on the reliability and durability of the Power Clamps that you implement. On an Automotive production line the requirement is for Power Clamps that last the life of the tooling without failure and without causing any downtime.

How do you specify the right Power Clamp for a particular application?

The first consideration is the size of the component that you’re clamping, the amount of space available in the production process and what kind of access you need to around the clamp. If you are clamping a very small component and you need to hold it close to the clamp, clearly a smaller clamp will be required.

The second consideration is the distance between the pivot point and the length of the clamp arm and the weight of the tooling

The third consideration is the amount of clamp force or the holding force you need the clamp to apply.

If you are using Grippers the weight of the clamp becomes very important. If you intend to mount the Power Clamp on the end of a robot arm it will have a weight limit. That will dictate the size of Clamp you use and what is made of.

What options are there for customisation of the Power Clamps that Sandfield supply?

On the bigger Power Clamp models we use oval cylinders which allows for a slim profile which is important on automotive production lines where space is often at a premium and access to the panels is required, originally to weld, although there is much more riveting and bonding more recently. In all of these instances access to the Power Clamps is required, so Power Clamps should be designed to have a thin form to allow space for access.

The Power Clamps that Sandfield supply are available with a range of different clamp arms, manufactured from steel, with different offsets and different clamp arm lengths

One of the options on the Power Clamps that we supply is a hand-applied mechanism. Normally a Power Clamp is fully automated, it goes on by air and it’s taken off by air. In some instances the operator might need to accurately position a component or locate a bracket, we provide an option where the clamp is manually applied by the operator, backed up by air then opened automatically. This hand-applied option is available on all of the Power Clamps in the Sandfield range.

There is also an option on the hand applied clamps to retain the clamp arm in the open position. When using a hand applied clamp the pneumatic cylinder needs to dump the air so the operator can apply it. Depending on the weight of the clamp arm tooling, the arm can fall shut, which makes it difficult for the operators to load the component. In these instances we provide the option of an internal retaining mechanism, that holds the clamp in the open position, stopping it from falling shut and allowing the operator to efficiently apply the clamp manually.

The 25, 40, 50 and 63 bore Power Clamps we supply also have the option of a gear mechanism which allows the clamp handle to be rotated 360 degrees. The hand-applied mechanisms are built into the clamp head, the benefit of having this is that it is sealed to withstand weld spatter, general dirt and water ingress.

Power Clamps can also be supplied with a range of opening angles, the normal opening angle ranges from zero to 135 degrees. In different applications you may need more clearance or you may need the arm to open at certain angle, if you haven’t got room to open it at the normal angles for example, the opening angle might need to be restricted.

How do Sandfield Engineering ensure the reliability and longevity of the Power Clamps that we supply?

The Power Clamps Sandfield supply have sealed clamp heads to stop the ingress of dirt and weld splatter and integrated sensing which detects if the Power Clamp is in an open or closed position.

The clamp head is also sealed with gaskets to stop water ingress into the head. They lock over center so in the event of an air failure the clamp will remain in its locked-on position with a manual release button which allows an operator to release the clamp arm if they need to remove it. Built into the clamp head, is something we call a positive stop, which eliminates any backlash from the clamp and ensures that the clamp arm comes into a repeatable position.

The inside of our clamp heads are fitted with Ina needle roller bearings, the pins and bushes are hardened and the main trunions are ground to eliminate any play. A combination of the high-quality needle roller bearings, the hardened pins, the ground trunion and a hard stop at the top of the track ensure high clamping forces, long repeatability over a period of time and a high number of cycles.

One of the requirements of the automotive industry is that Power Clamps are tested for a minimum of 3 million cycles to ensure a long life cycle in production.

Speak to Sandfield Engineering about your Power Clamp requirement.

Do not hesitate to call us on 0330 223 5344 or email sales@sandfieldengineering.com to speak to us about how we can be helping you to implement safety facilities around Lithium Battery production processes.