It’s a question that often comes up so as leading UK Stainless Steel Toggle Clamp suppliers we thought we would have a crack at answering it for you.

You may remember from our What is a Toggle Clamp post at the beginning of December that a Toggle Clamp is a tool used to securely locate components or parts in position, typically as part of a production, packaging or distribution process. The primary features of Toggle Clamps is that that they lock in position securely and are extremely quick acting, which means that they can be quickly activated and deactivated by an operator.

Toggle Clamps are most often used in production lines where components need to be held securely and then removed quickly in repetitive manufacturing processes.

Stainless Steel Toggle Clamps are exactly the same as regular Toggle Clamps except they are made from Stainless Steel.

So what difference does that make and why would you need a Stainless Steel Toggle Clamp?

Why would you need a Stainless Steel Toggle Clamp?

Stainless Steel Toggle Clamps are most often specified for four connected reasons:

- Aesthetics

- Corrosion Resistance

- Hygiene

- Life Cycle Costs

The aesthetics perhaps speaks for themselves, if your Toggle Clamp is going to be on display then it makes sense that it looks good. Stainless Steel is certainly one of the most aesthetically pleasing of metals.

The bigger benefit of Stainless Steel is its famous corrosion resistance.

Unless otherwise specified Toggle Clamps are normally produced from Mild Steel due to its malleability as well as its high tensile and impact strength. The one big issue with Mild Steel is that it has a high proportion of Iron to Carbon, which makes it very susceptible to corrosion.

This is why the majority of Mild Steel Toggle Clamps that Sandfield Engineering supply are Zinc Plated to overcome this shortcoming and improve the longevity of the clamps. Whenever you specify and design a clamp, or indeed any piece of industrial equipment, there is necessarily a trade off between aesthetic, strength and durability. If the primary requirement is strength then Mild Steel will often outperform other metals including Stainless Steel. However, if the Toggle Clamp is expected to perform outdoors, in wet or marine environments corrosion will very quickly affect the operation of a Mild Steel Toggle Clamp.

The harsher the environment the more consideration you have to give to protecting the clamp from corrosion. As a matter of course the vast majority of Toggle Clamps that we supply are coated with Zinc, in harsher environments we may coat the Mild Steel with Stainless Steel but there comes a point where Mild Steel is simply not feasible as a material, which is when you would have to specify a Stainless Steel Toggle Clamp.

For normal outdoor use we typically supply Stainless Steel Toggle Clamps produced from 304 Stainless Steel which is made up of 18% Chromium and 8% Nickel. In particularly harsh environments Stainless Steel 316 is often specified which is made up of 16% Chromium, 10% Nickel and 2% Molybdenum. 316 Stainless Steel is the second most common austenitic Stainless Steel, the Molybdenum delivers greater resistance to acids and local corrosion caused by chloride ions.

Why is Stainless Steel considered to be more hygienic?

Whilst it is common knowledge that Stainless Steel has amazing anti-corrosion properties it is perhaps less understood that Stainless Steel is one of the most hygienic industrial materials known. Stainless Steel is critical in the production, packaging and delivery of food, beverages and pharmaceutical products which require the highest standards of hygiene.

The life-cycle benefit of Stainless Steel comes from its anticorrosive qualities, clearly if a Stainless Steel Toggle Clamp doesn’t rust it will last longer.

How does Stainless Steel achieve these standards of good looks, anti-corrosion, hygiene and longevity?

The key to Stainless Steel’s aesthetic good looks, corrosion resistance, hygiene and longevity all come down to one characteristic that is known as The Passive Layer. The Passive Layer forms on Stainless Steels’ surface once there is more than 11% of Chromium in the alloy. Once the 11% Chromium threshold is achieved a thin Chromium Oxide coating develops when the Chromium reacts with the Oxygen in the surrounding environment. This layer is different from iron oxide or rust, because it is inactive or inert and doesn’t react with other chemical elements it comes in contact with.

It is this passive layer that provides Stainless Steel with it’s amazing anti-corrosive performance which contributes to it hygienic properties: because it doesn’t react to chemicals it is easy to clean, because it doesn’t corrode there are no holes or scratches to harbour dirt, because the material is inert is doesn’t impart colour or flavour to food, beverage or pharmaceutical products.

How do you go about specifying Stainless Steel Toggle Clamps?

Once you have established that you require a Stainless Steel Toggle Clamp the process of specification is similar to specifying any Toggle Clamp.

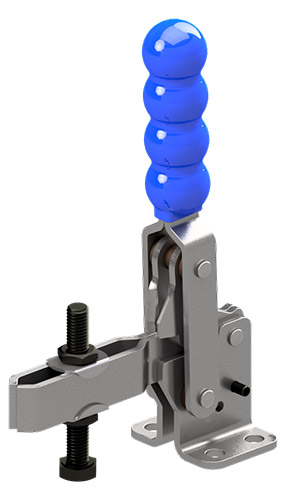

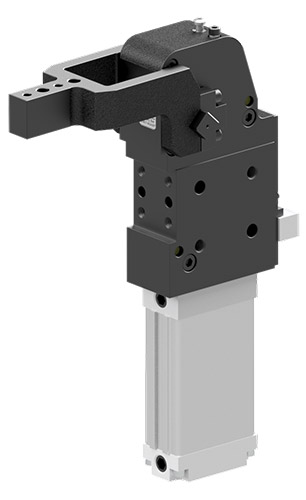

The first thing that you might notice is that the range of Stainless Steel Toggle Clamps is likely to be less broad than the full range of Toggle Clamps. Sandfield Engineering hold Vertical Stainless Steel Toggle Clamps, Horizontal Stainless Steel Toggle Clamps, Push Pull Stainless Steel Toggle Clamps and Pull Stainless Steel Toggle Clamps in stock and available for delivery on short lead times. Heavy Duty Toggle Clamps are characterised by their ruggedness and robustness, because they are made from Mild Steel and benefit from it’s malleability as and its high tensile and impact strength.

The second consideration in specifying any Toggle Clamp is the action that you require. You need to think about the space that you have in which to position the Toggle Clamp and the components that you are looking to clamp, this will dictate the action. If for example there is no space limitation above the clamp the likelihood is that you can use a Vertical Stainless Steel Toggle Clamp. If there is a lack of space above the clamp you will need a Horizontal Stainless Steel Toggle Clamp. If you need to keep to components apart you will need a Push Stainless Steel Toggle Clamp you need to hold two components together you will need a Pull Stainless Steel Toggle Clamp.

Once you have decided on the material and action you need to consider the size of the components you are looking to clamp, the space you need around the components, if you need clearance for other tools like welding guns or milling cutters or if you require safety features like secondary locks.

How can Sandfield Engineering support you with Stainless Steel Toggle Clamps?

Sandfield Engineering supply a range of Stainless Steel Toggle Clamps on our website. If the Stainless Steel Toggle Clamp you need isn’t available in our range feel free to get in touch and talk through our popular custom clamps design service. We will be happy to support you to pin down the perfect specification for your unique application, supported by our Toggle Clamp experts every step of the way.