Discover the various types of toggle clamps, each with unique designs and operational features, to help you choose the best one for your requirements.

In 2025, anything with the power to enhance productivity while ensuring safety is a sure bet for success. Toggle clamps meet this brief perfectly, offering precision, reliability, and efficiency across various industrial applications and manufacturing purposes.

But with so many toggle clamp variations on the market, how do you determine which type best suits your needs?

In this article, we’ll explore the different types of toggle clamps, their defining characteristics, and how to choose the ideal solution for your specific applications.

Toggle Clamp Market

Improving speed, precision, and overall efficiency across industrial and manufacturing processes, the global toggle clamp market is predicted to reach an overall value of $1.5 billion in 2033, growing at a 5.8% CAGR from 2025.

This toggle clamp demand is driven by sectors such as automotive, aerospace, and metalworking, where secure and repeatable clamping is essential for high-performance manufacturing.

Plus, the expansion of industrial automation, including robotics and assembly lines, further fuels the need for durable, high-precision clamping solutions.

Thanks to various toggle clamp technology enhancements in recent years, we’ve also seen an upsurge in their functionality and application scope, with new designs, configurations, and customisation features now available to the market.

9 Toggle Clamps Types

Toggle clamps come in a variety of designs, each tailored to suit different applications, clamping orientations, and holding forces.

Here are the main types of toggle clamps and their defining features:

- Vertical Toggle Clamps

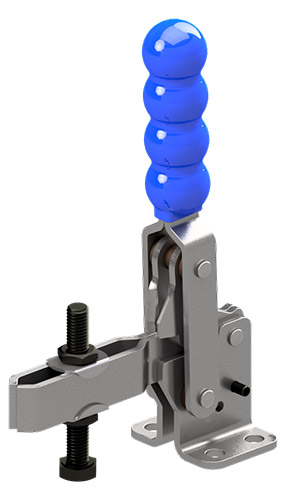

Starting with one of the most common types of toggle clamp, the vertical toggle clamp locks a workpiece in position with the handle moving vertically upwards, hence the name.

A vertical toggle clamp provides a reliable holding force, accommodating robust clamping requirements within confined spaces. Manually operated, with its simple pivot-and-lever mechanism, vertical toggle clamps come in various sizes and designs.

- Horizontal Toggle Clamps

Another widely used clamping solution is the horizontal toggle clamp. Operating in a similar pivot-and-lever mechanism, but as the name implies, a horizontal toggle clamp works in a horizontal direction.

By holding a workpiece securely via a handle parallel to the base, this toggle clamp design improves the operational safety in environments with potential overhead obstructions.

- Push Pull Toggle Clamps

A push pull toggle clamp operates through a linear action that either pushes or pulls your workpiece, depending on whether the handle is pushed forward or pulled back. With this functionality, push-pull toggles provide greater versatility, with tension and compression ideal for axial clamping.

Overall, the push-pull toggle clamp offers enhanced precision for linear tasks while avoiding sideways or alternative movement.

- Latch Toggle Clamps

Latch toggle clamps are typically used to fasten two objects together using a latch mechanism. Rather than a fixed clamping arm, it has a hook or latch mechanism that engages with an opposing plate.

Ideal for doors, lids, or moulds, when you push the handle down, the latch will tighten and lock over-centre, which is why this toggle clamp is also referred to as an “over-centre latch clamp”.

Latch toggle clamps come in a few varieties, such as “U-hook” latch clamps or “J-hook” latch clamps.

- Plier Toggle Clamps

Plier toggle clamps are portable clamping tools designed for quick and easy operation. Working on the same pivot-and-lever principles, they feature a hand-held plier-style design that enables users to apply clamping force directly without mounting.

Good for spot welding, bonding, and light assembly tasks where mobility and flexibility are essential, plier toggle clamps offer a compact design for efficient single-handed use, making them a practical choice for temporary or on-site clamping applications.

- Reverse Toggle Clamps

Reverse toggle clamps operate on an inverted mechanism compared to standard toggle clamps. Instead of the clamping arm moving toward the workpiece, a reverse toggle clamp moves away, suiting applications where traditional clamp motion could interfere with the work area.

Perfect for confined or complex operational environments, reverse toggle clamps still use an over-centre locking principle that ensures a secure clamping force.

- Pneumatic Toggle Clamps

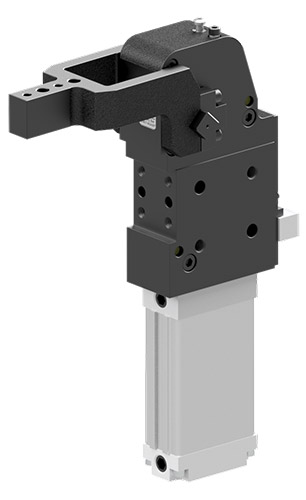

Unlike the manual operation mechanism across the former toggle clamps listed above, pneumatic toggle clamps offer advanced air-powered operation. This movement provides a user-friendly, rapid action, ideal for applications that require frequent and consistent clamping.

Due to their air-powered mechanism, pneumatic toggle clamps can be integrated seamlessly into automated processes, ideal for high-volume manufacturing applications.

- Heavy-Duty Toggle Clamps

Specifically designed for applications that require extra durability and high-clamping power, heavy-duty toggle clamps are typically made with reinforced components to maintain greater clamping strength.

Withstanding extreme mechanical stress, heavy-duty toggle clamps are good for welding, metalwork, and other heavier assembly operations.

With no particular design except to provide further durability than standard toggle clamps, heavy-duty toggle clamps are available in the various designs previously listed:

- Heavy-duty vertical toggle clamps

- Heavy-duty horizontal toggle clamps

- Heavy-duty push-pull clamps

- Heavy-duty latch clamps

Enhance Your Manufacturing with Precision-Engineered Toggle Clamps

At Sandfield Engineering, we’re toggle clamp experts, with over 50 years of engineering excellence.

Our team has partnered with some of the UK’s most renowned manufacturers and brands, including Jaguar Land Rover, Aston Martin, Ford, Bentley, Marks & Spencer, and Tesco.

We offer a comprehensive range of toggle clamps to suit every industrial application and manufacturing process.

Explore our toggle clamp selection today, and get in touch if you require any advice or support.