How Toggle Clamps Are Used Across Industries and Applications

From woodworking to automotive and electronics, get a better grip on what toggle clamps are used for and how they support multiple industries.

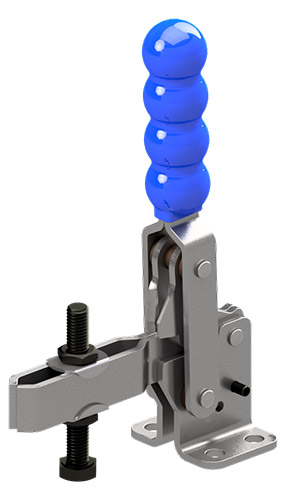

Whether you’re tackling a home DIY project or running large-scale industrial manufacturing, toggle clamps have one singular function that drives a $428 million industry – Securely fastening an object in place.

But with so many types of toggle clamps available, can you find one that suits your exact working needs?

In this article, we’ll answer the question: “What are toggle clamps used for?” and explore multiple practical applications across six key industries.

What Are Toggle Clamps Used For?

Toggle clamps are essential devices used across various industries and working environments to secure objects in place.

Many of these sectors and applications are safety-critical or highly regulated. Therefore, as a dependable clamping solution, the overall reliability, efficiency, and precision toggle clamps provide make them highly valued tools.

We’ve listed six general areas where toggle clamps are used for numerous applications:

- Woodworking

Not to be confused with traditional woodworking clamps, toggle clamps are ideal for securing workpieces in jigs and fixtures. The woodworking practices that benefit from toggle clamps include:

- Drilling

- Cutting

- Routing

- Sanding and finishing

- Planing and jointing

- Glueing and assembly

- Sawing and shaping

- Template work and jig building

Safer and more reliable than handheld alternatives, toggle clamps are a staple in woodworking environments due to their dependability, simplicity and versatility.

- Automotive Manufacturing

Of all sectors, the automotive industry generates one of the highest demands for toggle clamps. Precision, efficiency, and reliability are all essential in automotive manufacturing, which is why toggle clamps provide such a valuable application.

Key manufacturing operations that require automotive clamps include:

- “Body in White” (BiW) fabrication

- Welding and fabrication

- Assembly

- Machining and metalworking

- Bonding and glueing

- Testing

- Injection moulding

As a proven clamping solution, toggle clamps play an integral role in ensuring components remain perfectly stable throughout manufacturing operations. This benefit, alongside its quick action and locking features, makes automotive clamps highly effective tools for repetitive processes and high productivity.

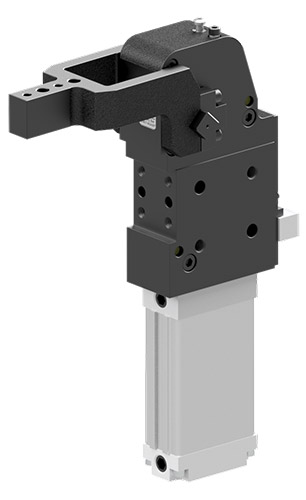

The emphasis on automation and smart manufacturing practices within manufacturing also favours automotive clamps because they provide a consistent and repeatable clamping force.

- Welding

Welding clamps are used to hold parts in jigs and fixtures during welding. Driven by various industries where welding remains a prominent application, toggle clamps continue to provide reliable, hand-free stability, ensuring precision, safety, and efficiency.

The industries that utilise welding clamps include:

- Construction and infrastructure

- Manufacturing

- Automotive and transportation

- Aerospace and aviation

- Energy (oil, gas, renewables)

- Shipbuilding and maritime

- Defence and military

- Agriculture

- Medical

- Machinery

Machine clamps are used to securely hold workpieces in place on various machinery applications, including:

- CNC machines

- Drilling machines

- Milling machines

- Lathes

- Presses (hydraulic or mechanical)

By keeping materials stable during intense cutting, drilling, or shaping, toggle clamps help maintain accuracy and prevent movement that could cause poor quality work or even damage the part or the machine.

Valued in both small workshops and large manufacturing facilities, toggle clamps bring a simple yet highly effective solution for consistent, precise machining.

- Electronics

Toggle clamps are widely used in the electronics industry for securing components during soldering, testing, or assembly.

The components that benefit from an electronics clamp during assembly include the following:

- Printed Circuit Boards (PCBs)

- Electronic devices and enclosures

- Surface-Mount Components (SMD/SMD packages)

- Microchips and Integrated Circuits (ICs)

- Connectors and terminals

- Sensors

- Small electronic modules

- Switches and buttons

- Battery packs and power components

- Displays

- Wire harnesses and cable assemblies

The growing electronics market has created a high demand for toggle clamps. You’ll find various designs used for electronic assembly, including vertical, horizontal and push-pull toggle clamps.

- Food Processing

Food processing companies employ toggle clamps for numerous applications across various stages of production, packaging, and equipment maintenance.

These applications may include:

- Securing sieve lids

- Holding equipment components

- Enclosures and access doors

- Jigs and fixtures

To reduce contamination risks and maintain high hygiene standards, food processing environments choose stainless steel toggle clamps, which offer excellent corrosion resistance and withstand intensive cleaning.

Find the Ideal Toggle Clamp for Your Application

With countless uses across woodworking, automotive manufacturing, welding, electronics, and food processing, having the right toggle clamp remains integral to the safety, accuracy, and productivity of your operations.

At Sandfield Engineering, we’ve spent over 50 years designing and supplying precision-engineered toggle clamps trusted by leading UK manufacturers.

Whether you’re working with wood, metal, electronics, or food-safe machinery, we provide an extensive range of toggle and engineering clamps. Every clamp we offer has been designed for impeccable performance in harsh industrial environments and is backed by our Sandfield Clamp Guarantee for complete confidence in long-term reliability.

If you need advice on the best solution for your application, get in touch with our expert team today.