OK, this is more of a reminisce rather than a case study but hopefully, you won’t mind indulging me a little.

2019 has been a momentous year for the Mini, celebrating their 50th year in production and producing their ten millionth car.

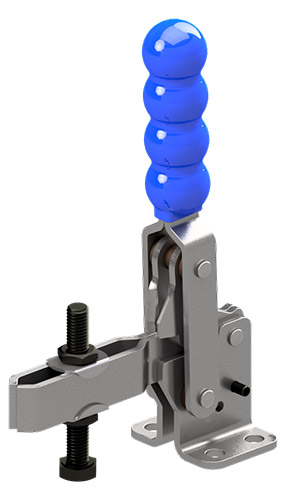

At Sandfield Engineering it blows our minds to think that we were involved in this iconic British project from the very beginning. The amazing thing is that in those days it happened that some guys working out of a shed in Sandy Lane, Titton were given the opportunity to provide the Toggle Clamps for a production line that would be producing the most iconic and most successful car ever.

And this isn’t the only time that Sandfield were engaged in massively important projects. We were also involved in the North Sea Pipeline project. Of course, I was a child at the time but I have vivid memories of the trucks constantly coming in and out of the yard, sometimes dozens a day.

I often wonder how my Dad felt walking into those meetings to present Sandfield Engineering’s capabilities on such important projects. Except of course, even if he had known how important these projects would turn out to be, it probably wasn’t like that in the 1960s and 1970s. The way we do business has changed, I imagine deals were done over a pint and a fag then, long before CAD and Microsoft Powerpoint were even imagined. He could have had no idea as he won those project that we would go on to become leaders in Automotive Hand Clamps and provide most of the world’s leading car manufacturers including Jaguar Landrover, Volvo, Ford and Aston Martin.

The other thing that has changed is the nature of the projects. It doesn’t feel like iconic projects like the Mini, or projects of national importance like the North Sea Pipeline happen so much these days. Most of the excitement now is around digital innovations which rely far less on the kind of engineering that we provide.

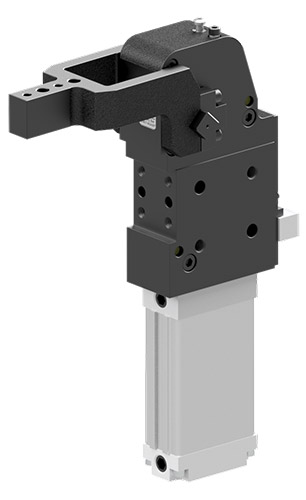

I like to think that my Dad would be proud to see that we have evolved with the times and are still busy providing solutions even if those are now more to with Industrial Automation, Custom Engineered Solutions and Water Pollution Prevention and not the huge infrastructure type projects he had so much success with. I suppose the closest thing we have now is the HS2 project and we expect to be involved if it gets approved and implemented.

The Mini is probably a great example of how manufacturing has evolved. The Mini was an entirely British innovation, engineered and manufactured in the UK. Manufacturing doesn’t happen like that anymore. The automotive industry in particular now relies on vast supply chains with components manufactured and assembled all over the world before shipped to the final assembly. The automotive has been proceeding with extreme caution with the inevitable onset of Brexit and it will be interesting to see how much automotive production will be going in the UK after we leave the EU.

If you have made it this far, thank you for indulging me.

If you are interested to find out how Sandfield could be helping to meet your specially engineered clamping challenges contact us now.